A little unusual one this time. David brought in his work truck for a

full system. Not unusual till you hear the equipment. All DynAudio

Esotar that's right Esotar. David wanted a serious upgrade to the system

he had and I think he got it. We will be adding the Esotar E110, E650

and E1200 in a full active set up.

Now for starters he had another shop do the first install which to say

was a little lack luster. I had to gut all the previous wiring before I

started. This type of stuff just infuriates me. This is why I tell

people you need to get picks everything a shop does.

With the truck back to stock so to say I started in with the doors. The doors will be getting a layer of Hush Mat Ultra sound deadening

on the outside skin and inside skin along with a layer of Silencer

Megabond foam insulation on the inside skin. The doors will be getting

the E650's as well.

Before I did the inside skin I had to close up the big holes in the door

skin. I tried something new this time around. I used a piece of 1/8"

ABS that I was able to heat form to the contours of the door. With a few

screws I had made panels that could be sound deadened and removed to

service the door if need be.

With that done I moved on to the mounting rings for the woofers. True to

form I used 3/4" plexiglas and used rivet nut fasteners to fasten them

to the doors.

With those done I could move on to finishing the door.

Up next was the custom a-pillars to house the E110's. They were laser

aligned to the center of vehicle at the listening level as well.

I made removable grill covers to conceal and protect the tweeters for

daily driving use. The inside edge of the ring I radius to help the

sound waves roll off to reduce reflection.

Now as usual with me attention to detail is off the richter scale. On advice from Steven Hill at Straight wire

I applied foam tape to the chassis of the truck then ran all the wiring

over it will strapping it down with more foam tape. The process is to

eliminate mechanical noise from entering the cables. Yes I said

mechanical noise. Steve told me that even though you may strap a wire

down but it still moves against the chassis of the vehicle and can

induce mechanical noise. Now I learn something every day and this is new

to me but it makes sense.

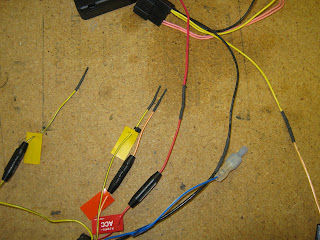

While on a wiring kick I did the wiring harness for the radio. All

connections were soldered and heat shrunk. On the aftermarket wiring

harness it had speaker

wires out so since I wasn't going to be using them I removed them from

the harness. After everything was done fabric electrical tape was used

to make it look more OEM.

David went with the Pioneer DEX-P99RS for processing. Now it being a SQ

deck only it was a little different in size so a little playing around

had to be done with the mounting kit. The radio had to be spaced out a

bit to fit inside the dash but it doesn't stick out to far. I actual

like the way it looks

Last thing on the docket was the subwoofer

enclosure. I used the BlackHole Stuff enclosure fill to improve the

acoustics of the enclosure. This stuff (pardon the pun) does magic.

The E1200 in it's new home. I also made a removable grille for the subwoofer as well.

David wanted to use the amplifiers from his previous install for now but

a set of Arc Audio Se is on the way so I'll update this build when they

go in. Since I was cleaning up everything I cleaned up the wiring going

to the amplifiers. The amplifiers before were just screwed to the

chassis of the truck this time I mounted them to a piece of carpeted

MDF.

Now a final shot of everything installed.

As

with the DynAudio Esotar the realism that is produced is something that

needs to be experienced. Words don't do it justice but that's the

DynAudio Esotar.

For more pics please visit Octave : Orlando and Central Florida source for high end car audio

For more pics please visit Octave : Orlando and Central Florida source for high end car audio